|

Notes and Tips:

Run in time - Give the new belt at

least 1 hour of use to run in before serious listening.

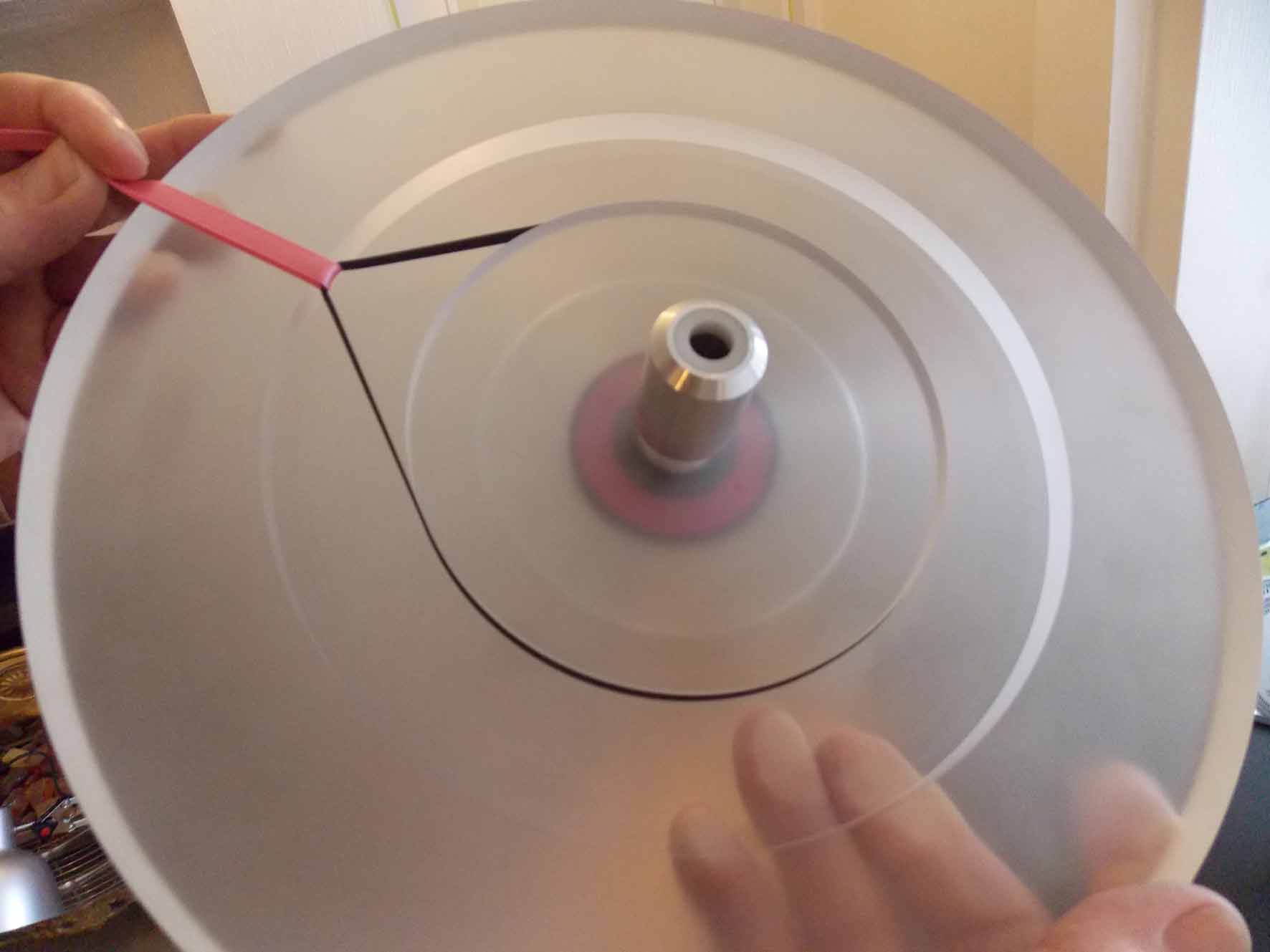

Belt inner and outer side - The belt will sound better on one side than

the other so it is worth experimenting and marking a line on what you prefer as

the “outer" side with a felt pen or dot of paint.

Belt Tension and Motor Angle - To avoid mechanical noise, and sound best,

the belt should have

the lowest tension without incurring wow and flutter-You can experiment with

tension, to hear

what sounds best. Belt height and speed can be altered on some decks.

Talc powder - This often helps to eliminate mechanical sound - All belts

seem to perform at their best with a little talc powder wiped over the surface.

Cleaning - The belt should not be treated with rubber conditioners,

polishes etc. All that is needed is a wipe over with water (not soapy water) or

methylated Spirit (not White Spirit).

Clean running surfaces - The belt running surface of your pulley,

sub-platter or platter are best cleaned with methylated Spirit from time to time

especially if they start to build up black rubber deposits.

Belt Life - It is normally recommended that standard rubber belts are

changed every 2 years or so, regardless of use. This is because rubbers age,

however the ageing process varies with the type of rubber, usage, temperature

and other factors.

|

DRIVE BELTS

for

DRIVE BELTS

for